SAFE is a key player in the creation of Compressed Natural Gas (CNG) stations for the automotive market. Our technical expertise has enabled us to design, build and install more than 3000 compression units in the world of Compressed Natural Gas. SAFE is able to respond to any specific requirements with a variety of competitive solutions thanks to: compression units with direct coupling to an electric motor or gas engine, design pressure reduction and measurement systems and storage pack.

Maximum refuelling speed

Minimum energy consumption for compression/decompression

High reliability and availability

Footprint

Scalability

High capacity CNG stations for trailers. Solution based on heavy duty compressors, high efficiency and performance. Driven by electric motor or gas engine.

Mechanical or hydraulic compressors are suitable for daughter stations to meet Customer requirements.

Turnkey mobile solution. Available with electric motor or gas engine.

A small number of buses refuelled at the same time with the shortest filling time thanks to high flow-rate compressors and fast refuelling dispensers.

All buses are connected to the filling points and are refuelled at the same time. Dispensers without mass meter and electronic head are used.

Slow refuelling where buses are refuelled while parked. Sequential filling managed by an automated system (card readers or similar).

Compared to conventional diesel, natural gas combustion cuts pollutants by half, thus reducing pollution in populated areas. A solution that is increasingly widespread in Italy and throughout Europe: in 2020, a total of 4,000 CNG distributors in Europe, including 1,400 in Italy, contributed to reducing CO2 emissions (g/Km) by 9.1% compared to the previous year.

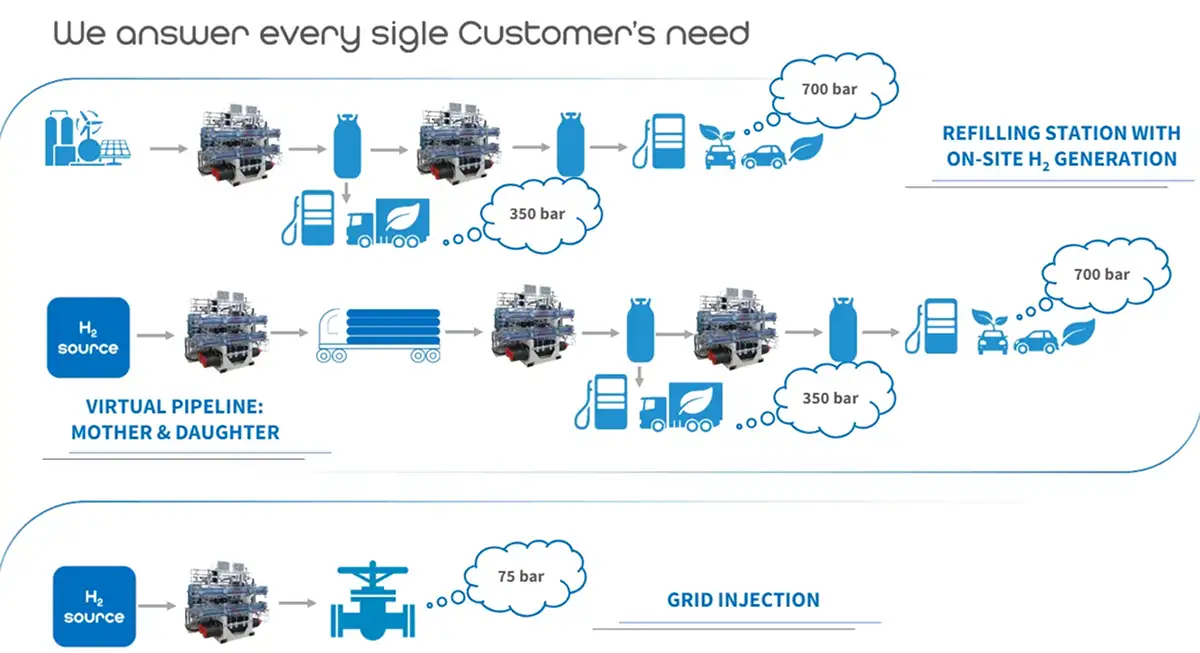

Prior to Safe S.p.A.’s intervention, hydrogen is generated by electrolysis of water or reformation of natural gas. Once produced, the raw hydrogen is ready for compression and distribution. Safe S.p.A. handles the compression and delivery of hydrogen for automobiles and infrastructure, ensuring efficient and safe use.

Hydrogen compression solutions

Storage, Grid Injection and Virtual Pipeline

Distribution - Filling stations and mobile unit

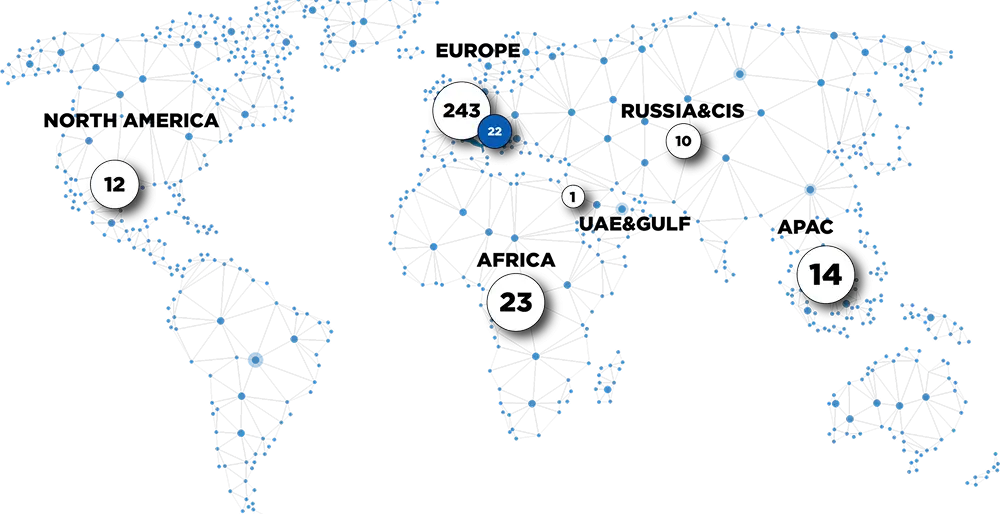

More than 300 units in operation worldwide

CUSTOMER PROXIMITY

Green Hydrogen

Blue Hydrogen

Gray Hydrogen

Yellow hydrogen

Purple Hydrogen

Brown Hydrogen